Simple, Effective Electromagnetic Fluid Filtration

WHY BALLMATRIX®? AN ELECTROMAGNETIC FLUID FILTRATION SOLUTION

The BallMatrix® Electromagnetic Fluid Filtration System from Milhous Company effectively removes suspended, magnetically susceptible material from process streams. Designed for automatic operation, this filtration system offers long-term cost and time savings as compared to traditional permanent magnet filtration systems. It removes 99% of magnetic contaminants, generates no waste products, and can operate under much higher temperatures and flow rates than traditional filters. Our proprietary design is configurable to existing systems for ease of use. Learn more about how our BallMatrix® filtration system works and why it would be beneficial for your operation.

HOW BALLMATRIX® FILTERS WORK

BallMatrix® filters use electromagnetic filters (EMFs) for iron removal from fluid systems. The original purpose for EMFs was to eliminate magnetite (Fe3O4) from nuclear power systems and boiler condensate, where it is commonly present. However, these filters are also highly effective at removing cobalt, chromium, nickel, and other materials that form ferrites or spinel crystals.

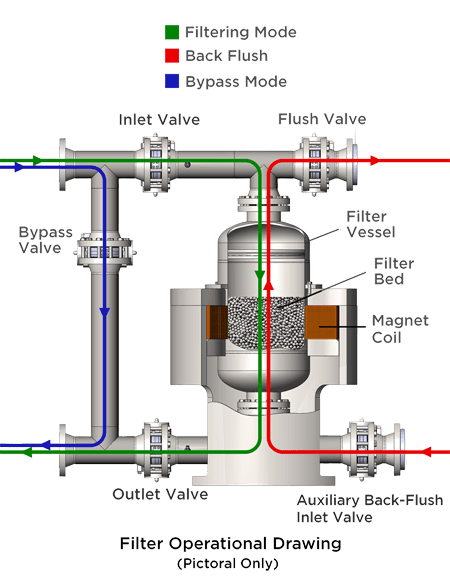

EMF filters intensify magnetic force within a matrix to attract magnetic particles. The Milhous BallMatrix® filtration system utilizes a pressure vessel of carbon steel containing small, magnetizable stainless steel balls surrounded by a magnet coil and a corresponding cooling circuit. During electromagnetic fluid treatment operations, the magnet coil generates a magnetic field in the filter bed. The filter bed is made up of small, magnetically susceptible stainless spheres to create a more intense, localized magnetic field where they touch. When process fluid is moving through the bed, suspended magnetic particle material is captured by the localized magnetic fields. Once the filter bed is fully loaded with contaminates, the filter system is bypassed and flushed.

Cleaning the BallMatrix® filter is simple. According to preprogrammed time intervals, the filter automatically de-magnetizes the filter bed and reverses process flow through the bed, causing the magnetic spheres to tumble against each other for about 10 seconds. This tumbling action is key to removing accumulated debris from the spheres, resulting in a completely clean filter bed. The entire flushing process takes approximately two minutes, and the frequency of flushing will depend on the concentration level of magnetically susceptible contaminates.

Benefits of BallMatrix® Filters

- Increased efficiency of fluid process: Filters extend the life of a process system by greatly reducing magnetically susceptible contamination from your process fluid.

- Efficiency in operation: A model 22 uses 14 amps of power for normal operation. A typical backwash for model 22 uses 681 Liters (150 Gal.) of process fluid.

- Decreased maintenance: A filter bed is designed for a 40-year life and does not require any maintenance for the life of the filter.

- Lowered energy costs: Filters decrease downstream fluid quality equipment fouling.

How BallMatrix® Compares to Other Filtration Systems

Typical filters produce a magnetic field that collects particles using separator magnets to pull and remove ferromagnetic contamination from processed material. Once the process is complete, users can remove the filter, washing away the captured particles. Factors like the size and design of the flow chamber, flow path, and total surface area of the magnetic loading zones influence the separation rate, the size of particles being separated, and the total capacity of particles retained by the separator.

Our uniquely designed BallMatrix® filters offer long-lasting advantages and increased efficiency as compared to permanent magnet filtration. BallMatrix® generates multiple electromagnetic fields amongst the magnetized stainless steel balls rather than using a single stationary magnet. This allows BallMatrix® filters greater coverage, removing magnetic particles of iron down to 0.08 µ for 99% filtration. Permanent magnet filtration systems utilize a single large magnet that eliminates only 60 to 70% of particles sized as small as 10-20 µ. Using one magnet lowers the likelihood that material will come into contact with it for filtration. These systems usually require multiple processes with a permanent magnet system and magnetic filtering to remove iron particles, whereas with a BallMatrix® system, if a particle is magnetic, the filter will effectively remove it.

Permanent magnets require regular manual cleaning and maintenance, even with hydraulic scraping devices. This necessitates hours of system downtime, intensive labor, and budgeting for replacement parts. While using permanent magnet filtration is cheaper initially, constant maintenance needs and production loss can cancel out that budgetary advantage. Alternatively, the BallMatrix® system averages a two-year ROI and, as a faster, fully automated system featuring a back-flush function that requires less than two minutes for cleaning, no manual maintenance intervention is necessary. Also, BallMatrix® systems operate with little power consumption, around 16.5kVA.

As permanent magnets require manual cleaning and filter changing, workers must handle exposed magnetized components, which can result in injuries. BallMatrix® users simply handle a touch screen for process operation, with no documented cases of injury over the last 50 years in the industry due to the shielded magnetic field.

Common Applications and Industries Served

Though the robust BallMatrix® filter was originally developed for use within the nuclear power industry on the secondary side of reactors, its applications have since expanded to include:

- Boiler systems: Magnetite formation within a steam boiler system is costly due to increased maintenance, lost production time, and reduced boiler life span. The mature technology of the BallMatrix® filtration system has been used predominantly in industrial magnetic water treatments for industrial sectors like pulp and paper mills, filtering magnetite out of condensate from boilers and heat exchangers. The BallMatrix® filtration system can sufficiently handle the large flows required to efficiently filter out magnetite from large condensate streams.

- Paint systems: The automotive industry uses BallMatrix® filters to remove 99% of weld balls and weld splatter from pretreatment or E-coat paint. This eliminates the likelihood of defects on one-coat paint vehicle surfaces, which would otherwise require manual rework, without diminishing the paint’s quality.

- Fluid process streams (all fluids): A BallMatrix® filtration system has superior efficiency in the industrial fluid filtering of iron, removing magnetically susceptible particles from any fluid regardless of particle size, viscosity, or flow rate. In oil and gas refining, BallMatrix® filtration systems can remove fluid and particulate contaminants from feed streams and fluid recirculation processes, effectively improving downstream refining efficiency, minimizing maintenance downtime, and extending equipment lifespan. A BallMatrix® system is also useful for recovering precious metals contained in concentrated or diluted solutions, which is particularly helpful due to the diminishing availability of mineral sources, increasing demand, and environmental concerns.

Regardless of the application, our EMF filtration solutions are equally effective across diverse industries and fluid types.

Contact Milhous for Premium Electromagnetic Fluid Filtration Solutions

While the BallMatrix® Electromagnetic Fluid Filtration System is more expensive than traditional systems, its proprietary design offers higher filtration and operational efficiency, better functionality, lower ongoing costs, and reduced safety risks for a wide variety of applications. At Milhous, our team will work closely with you to determine your unique needs, such as American versus European systems or existing system requirements, to best configure a filtration solution for your application.

Our company adheres to the highest quality standards and is ISO 9001:2015 certified for our quality management system. This assures that our products and services meet our strict quality standards and demonstrates our commitment to ensuring customer satisfaction and continuous improvement.

Contact us today for more information about our BallMatrix® EMF systems.